Upgrades

This upgrade concerns the oven chain group, equipped with a new type of chain links, mandril and preform rack.

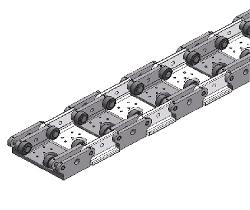

One of the main innovations concerns each link of the oven chain: the new model features additional retainers (represented in grey in the picture 1) which ensure more robustness and longer life of the chain.

The double tightening reduces the chain elongation and ensures more precision during the preforms pick-up and release, thanks to the reduction of links coupling back-lash.

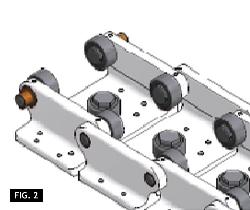

Picture 2 is an example of the old chain with single-tightening link.

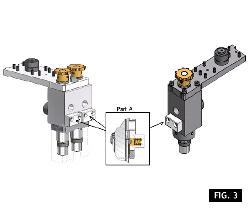

The new solution also includes the upgrade of the preform picking mandrils, in order to upgrade it to the latest version. The new mandrils, be they double or single (see picture 3), feature a spring plunger keeping them in the right position to transfer the preform (the mandril is pushed downwards and blocked with Part. A), thus ensuring an optimal picking of the preform neck and avoiding additional guides to keep the mandril pushed, especially in the upper part of the oven where the preform is overturned.

This implementation minimizes the need of maintenance intervention for the oven, since there are no guides/bearings to be replaced, because the mandrils are kept in position by the spring plunger.

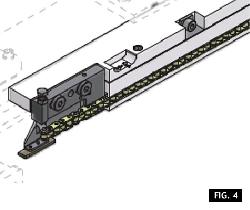

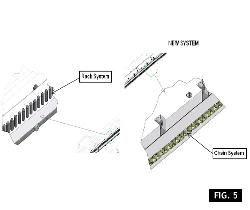

In order to improve the performance and to minimize maintenance, the upgrade also concerns the mandril rack, which has been equipped with a chain system instead of a pin system.

The new rack is composed of standard modules, which ensure easier maintenance and give the possibility to replace each module independently, without needing to change the whole section (upper or lower); moreover, the chain system makes the movement smoother, by avoiding jams of the single pins.

Thanks to the chain system, also the mandril accelerators are more efficient (at the beginning of the rack, see picture 5).

Minimum requirements:

- Available on all standard models and HC models; please communicate the machine pitch.

- As a supply integration, install the retrofit code ZF010100 concerning the machine controls.

Benefits

- Reduction of back-lashes and chain elongation

- Longer life of the system

- Better transfer of the preforms, thanks to a more reliable group

Contacts

Contact us

- SMI S.p.A.

- Address: Via Carlo Ceresa, 10

24015 San Giovanni Bianco BG

Italy - Phone: +39 0345 40.111

- E-mail: info@smigroup.it

- Monday - Friday: 07:45 - 17:30

Saturday - Sunday: Closed

Privacy statement

DATA PROTECTION AND PRIVACY

The European Regulation 679/2016 (GDPR) on the protection of personal data has been fully applicable since May 25th, 2018. This is an important goal, because it lays down rules relating to the processing of personal data for all Countries within the Union. Every company of the SMI Group planned a series of activities, assets or operational modes to comply with the regulation and put into practice the protection of personal data. Here is a list of actions taken to comply with the European Regulation and our policy on personal data processing.

![]()

Lawfulness of processing

All activities relating to personal data processing shall be lawful (consent, contract obligations, vital interests of the data subject or of third parties, compliance with legal obligations to which the controller is subject, public interest or exercise of official authority, legitimate interest pursued by the controller or by third parties).

![]()

Information document

The information statement has been improved and updated to the new regulations (art. 13 and 14 GDPR).

![]()

Rights of the data subjects (right of access, right to erasure-right to be forgotten, right to restriction of processing, right to object, right to data portability)

Technical and organization measures have been adopted to ensure the data subject's exercise of his rights and to meet the data subject requirements.

![]()

Controllers, processors

Based on the new principle of “accountability”, SMI Group organization was re-defined, in order to proactively ensure integral compliance with the Regulation.

Redefinition of the role of data processors and service suppliers whose activity implies personal data processing.

![]()

Risk of data processing; accountability measures taken by controllers and processors (Impact assessment, record of processing activities, security of processing, data breach)

The “Conformity document”, including records of data processing activity, plans, adopts and demonstrates all technical and organizational measures taken to adequately perform the data processing activities and specifies the necessary procedures to be adopted to notify data breach.

![]()

Transfer of personal data to international organizations

Smi Group adheres to the general principles and guarantees concerning the transfer of personal data to third Countries.

The Controller is:

SMI S.p.A.

Head office: Via Carlo Ceresa, 10 - 24015 San Giovanni Bianco (BG) - ITALIA

P.I.: 04471940165 - C.F.: 03942700166 - R.E.A.: 421708

For further information, write to: privacy@smigroup.net

According to the European Regulation 679/2016, the data subject is entitled to exercise the rights set forth in the Regulation.

The integral version of art. 15; 16; 17; 18; 20; 21; 77 of the European Regulation is attached to this document.

In order to exercise your rights, please send the application form duly filled in to the Controller's address.

Legal notice

SMI S.p.A. con Unico Socio

Società sottoposta a direzione e coordinamento da SMIGROUP S.p.A.

Società appartenente al GRUPPO IVA SMI INDUSTRIES

Sede amministrativa e Unità produttiva:

Via Carlo Ceresa, 10 - 24015 San Giovanni Bianco (BG) - ITALIA

Tel. +39 0345 40.111 - Fax: +39 0345 40.209 - www.smigroup.it

C.F. 03942700166 - P. IVA IT04471940165 - R.E.A. 421708

Iscr.Reg.Imprese 03942700166 - Cap. Soc. € 5.000.000 i.v.

Sede legale: Via Monte Grappa, 7 - 24121 Bergamo (BG) - ITALIA