Upgrades

ZF010007/8 - Knife group with motorized blade for single and double lane SK shrinkwrappers

Machines: SK

Benefits: Efficiency increase - Technology update

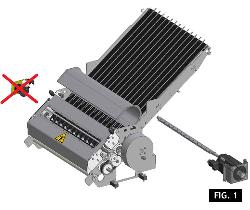

The upgrade consists in the replacement of the entire cutting unit with a new, more efficient model, easier to maintain.

This is part of a series of new solutions studied by SMI in order to upgrade to the latest version all the machines already installed on site.

The new group differs from the previous version for a lot of points, including the addition of a brushless motor dedicated to the rotation of the cutting blade and the possibility to open the housing area of the knife and rubber rollers by means of a hinge system and pressure spring designed for this purpose.

Thanks to the installation of this motor, the rotating speed of the blade becomes independent from the speed of the film climb belts: as a consequence, the edge of the cut looks sharper and without fraying; moreover, the cutting operation is more reliable and efficient, also with thicknesses that were problematic with the old clutch system.

The new group minimizes the maintenance costs and time, thanks to the elimination of the electro-pneumatic part that tends to lose efficiency over the time and requires frequent maintenance and adjustments, in order to ensure top-level performance. The use of the motor instead of the clutch has eliminated any inefficiencies due to delay in response times of the components, such as the clutch opening spring, the activation valve and the locking cylinder.

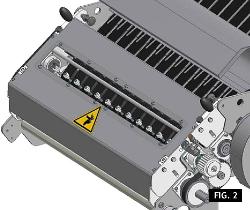

In order to make maintenance operations easier and in order to ensure a longer life of the cutting group, the restyling introduced new materials and new surface treatments against corrosive agents, such as rust. Some surface treatments also increase the machine hygienic level, by making the cleaning operations easier.

In case this product were taken into consideration for a machine manufactured before the year 2005, there is another important improvement of the functional group ZF010007/8, as compared to the old version installed on the above mentioned series of machines: the knife hinged opening. As a consequence, it is easier to intervene on a rubber roller or to replace the cutting blade.

The blade area is also integrated with a window which makes the group inner parts visible, while it is operating, without affecting the safety levels thanks to a transparent protection. As a consequence, it is possible to follow the cutting process and point out any anomalies from the privileged point of view offered by this window.

If not specified, this offer does not include installation and commissioning of the group.

Database to be provided, in order to update the machine parameters.

Minimum requirements:

From SK 2° series and Combi machine (with gefran thermoregulator installed)

Benefits

- Improved cutting efficiency at all speed rates;

- Higher precision of the cutting edge;

- Higher reliability of the cutting process, with different film thicknesses;

- Easier and faster maintenance operation.

Contacts

Contact us

- SMI S.p.A.

- Address: Via Carlo Ceresa, 10

24015 San Giovanni Bianco BG

Italy - Phone: +39 0345 40.111

- E-mail: info@smigroup.it

- Monday - Friday: 07:45 - 17:30

Saturday - Sunday: Closed

Privacy statement

DATA PROTECTION AND PRIVACY

The European Regulation 679/2016 (GDPR) on the protection of personal data has been fully applicable since May 25th, 2018. This is an important goal, because it lays down rules relating to the processing of personal data for all Countries within the Union. Every company of the SMI Group planned a series of activities, assets or operational modes to comply with the regulation and put into practice the protection of personal data. Here is a list of actions taken to comply with the European Regulation and our policy on personal data processing.

![]()

Lawfulness of processing

All activities relating to personal data processing shall be lawful (consent, contract obligations, vital interests of the data subject or of third parties, compliance with legal obligations to which the controller is subject, public interest or exercise of official authority, legitimate interest pursued by the controller or by third parties).

![]()

Information document

The information statement has been improved and updated to the new regulations (art. 13 and 14 GDPR).

![]()

Rights of the data subjects (right of access, right to erasure-right to be forgotten, right to restriction of processing, right to object, right to data portability)

Technical and organization measures have been adopted to ensure the data subject's exercise of his rights and to meet the data subject requirements.

![]()

Controllers, processors

Based on the new principle of “accountability”, SMI Group organization was re-defined, in order to proactively ensure integral compliance with the Regulation.

Redefinition of the role of data processors and service suppliers whose activity implies personal data processing.

![]()

Risk of data processing; accountability measures taken by controllers and processors (Impact assessment, record of processing activities, security of processing, data breach)

The “Conformity document”, including records of data processing activity, plans, adopts and demonstrates all technical and organizational measures taken to adequately perform the data processing activities and specifies the necessary procedures to be adopted to notify data breach.

![]()

Transfer of personal data to international organizations

Smi Group adheres to the general principles and guarantees concerning the transfer of personal data to third Countries.

The Controller is:

SMI S.p.A.

Head office: Via Carlo Ceresa, 10 - 24015 San Giovanni Bianco (BG) - ITALIA

P.I.: 04471940165 - C.F.: 03942700166 - R.E.A.: 421708

For further information, write to: privacy@smigroup.net

According to the European Regulation 679/2016, the data subject is entitled to exercise the rights set forth in the Regulation.

The integral version of art. 15; 16; 17; 18; 20; 21; 77 of the European Regulation is attached to this document.

In order to exercise your rights, please send the application form duly filled in to the Controller's address.

Legal notice

SMI S.p.A. con Unico Socio

Società sottoposta a direzione e coordinamento da SMIGROUP S.p.A.

Società appartenente al GRUPPO IVA SMI INDUSTRIES

Sede amministrativa e Unità produttiva:

Via Carlo Ceresa, 10 - 24015 San Giovanni Bianco (BG) - ITALIA

Tel. +39 0345 40.111 - Fax: +39 0345 40.209 - www.smigroup.it

C.F. 03942700166 - P. IVA IT04471940165 - R.E.A. 421708

Iscr.Reg.Imprese 03942700166 - Cap. Soc. € 5.000.000 i.v.

Sede legale: Via Monte Grappa, 7 - 24121 Bergamo (BG) - ITALIA