Upgrades

ZF010011 - Belt automatic centering systems

Machines: SK

Benefits: Efficiency increase - Technology update

The upgrade consists in the replacement of the belt groups with state-of-the-art groups featuring a new design in the driving and centering system.

This is part of a series of retrofitting studied by SMI in order to upgrade to the latest version all the machines already installed on site.

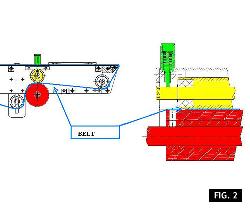

In the system previously installed, the belt was driven by a traction roller (red part, picture no.2) on which the belt (blue part, picture no.2) was wrapped and pressed by means of a counter-roller (yellow part, picture no.2) and of a pressing device (green part, picture no.2).

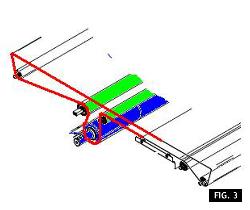

This upgrade offers a new mechanical solution, by eliminating the counter roller and the pressing devices (see color picture, no.3). The new solution offers several advantages and fits a larger range of belts (double-layer or single-layer belts), thus reducing the radial plates and the empty space between one belt and another, in case you choose a single-layer belt.

Thanks to the flexibility of the new system, all anomalous tensions are eliminated and the traction friction is reduced; as a consequence, the surface temperature is reduced, thus allowing a smooth transportation of the product and a reduction of the belt wear.

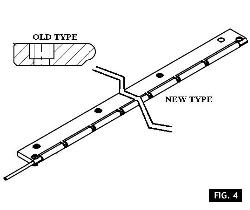

This upgrade includes the supply of a new type of “long-life” roller plates, which avoid the belt friction on the dead plate, ensuring longer life of the belt.

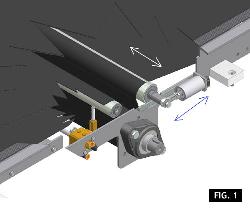

The pneumatic system checking the belt side movement ensures a constant correction of the belt position (picture no.1), preventing any tears due to fortuitous contact with external elements; the new application ensures a more dynamic group, always granting an excellent traction, independently of the external surface wear and always compensating any extension of the belt (within reasonable limits).

Moreover, the regulation in case of belt replacement is easier, because the system does not require manual adjustments, except for the positioning of the three-way valve; by contrast, the previous system needed a technician for the adjustment of the counter-roller and it was necessary to periodically check that the adjustment did not cause the belt deviation.

If not specified, this offer does not include the installation and start-up of the new group.

Minimum requirements:

For all “SK” shrink-wrappers.

Benefits

- Automatic centering of the belts;

- Belt longer life;

- No tearing due to anomalous wear;

- No operator's intervention;

- Reduced energy consumption of the gear-motors operating the belts.

Contacts

Contact us

- SMI S.p.A.

- Address: Via Carlo Ceresa, 10

24015 San Giovanni Bianco BG

Italy - Phone: +39 0345 40.111

- E-mail: info@smigroup.it

- Monday - Friday: 07:45 - 17:30

Saturday - Sunday: Closed

Privacy statement

DATA PROTECTION AND PRIVACY

The European Regulation 679/2016 (GDPR) on the protection of personal data has been fully applicable since May 25th, 2018. This is an important goal, because it lays down rules relating to the processing of personal data for all Countries within the Union. Every company of the SMI Group planned a series of activities, assets or operational modes to comply with the regulation and put into practice the protection of personal data. Here is a list of actions taken to comply with the European Regulation and our policy on personal data processing.

![]()

Lawfulness of processing

All activities relating to personal data processing shall be lawful (consent, contract obligations, vital interests of the data subject or of third parties, compliance with legal obligations to which the controller is subject, public interest or exercise of official authority, legitimate interest pursued by the controller or by third parties).

![]()

Information document

The information statement has been improved and updated to the new regulations (art. 13 and 14 GDPR).

![]()

Rights of the data subjects (right of access, right to erasure-right to be forgotten, right to restriction of processing, right to object, right to data portability)

Technical and organization measures have been adopted to ensure the data subject's exercise of his rights and to meet the data subject requirements.

![]()

Controllers, processors

Based on the new principle of “accountability”, SMI Group organization was re-defined, in order to proactively ensure integral compliance with the Regulation.

Redefinition of the role of data processors and service suppliers whose activity implies personal data processing.

![]()

Risk of data processing; accountability measures taken by controllers and processors (Impact assessment, record of processing activities, security of processing, data breach)

The “Conformity document”, including records of data processing activity, plans, adopts and demonstrates all technical and organizational measures taken to adequately perform the data processing activities and specifies the necessary procedures to be adopted to notify data breach.

![]()

Transfer of personal data to international organizations

Smi Group adheres to the general principles and guarantees concerning the transfer of personal data to third Countries.

The Controller is:

SMI S.p.A.

Head office: Via Carlo Ceresa, 10 - 24015 San Giovanni Bianco (BG) - ITALIA

P.I.: 04471940165 - C.F.: 03942700166 - R.E.A.: 421708

For further information, write to: privacy@smigroup.net

According to the European Regulation 679/2016, the data subject is entitled to exercise the rights set forth in the Regulation.

The integral version of art. 15; 16; 17; 18; 20; 21; 77 of the European Regulation is attached to this document.

In order to exercise your rights, please send the application form duly filled in to the Controller's address.

Legal notice

SMI S.p.A.

IVA SMI INDUSTRIES Group

Headquarters: Via Carlo Ceresa, 10 - 24015 San Giovanni Bianco (BG) - ITALIA

Registered office: Via Monte Grappa, 7 - 24121 Bergamo (BG) - ITALIA

VAT: 04471940165 - TAX code: 03942700166 - R.E.A.: 421708

Share capital: Euro 5.000.000 i.v.