History

Smigroup’s origins date back to the mid-‘70s, when Luigi Nava sets up a machine shop in San Pellegrino Terme (Bergamo). The small enterprise is managed not only by the founder, but also by his four sons, who start working there at the age of 18. In the beginning the craftsman’s small enterprise activity is represented by machine finishings for third parties. Some years later such activity is enlarged to the maintenance and repair of machinery and equipment employed in the bottling and packaging lines of the beverage industry. The passion for chains and gears and youth’s spirit of initiative push Nava brothers, under their father’s careful eyes, towards an even more ambitious goal: to manufacture a packaging machine characterized by innovative solutions and wide operating flexibility.

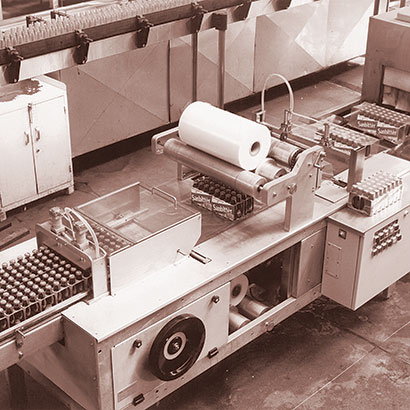

The first packer (called “shrinkwrapper”) comes to light: the APET series is born, and it immediately catches the market’s attention. In the same year, in addition to the “F.lli Nava” machine shop, the limited liability company SMI (Sistemi Macchine Impianti) Srl is established.

SMI officially presents its shrinkwrappers in the occasion of “SIMEI” international exhibition in Milan. In the same year SMI also manufactures the first overlapping cardboard sleeve multipacker of the MTB series (then MP), achieving the speed of 100 packs/minute.

The company’s staff raises from 4 to 11 employees and doubles in the following year.

SMI presents the ABAS series of sealing bar packers.

The machine production increases from 7 units in 1990 to more than 50 in 1993, including the new medium-low speed shrinkwrappers of the AF series and the new handle applicators of the MAB series.

The year of the big change: SMI Srl moves its headquarters to San Giovanni Bianco (Bergamo) in a modern industrial complex of 7,600 sqm (in the following years they will become 65,000 sqm), which allows a remarkable increase in the manufacturing capacity. In the year 1994 the machine production bounces to over 100 units and the workforce goes up to 90 people.

The transformation from S.r.l. to S.p.A. takes place and the new-born joint-stock company closes the year with a sales volume of 23 billion liras (equal to 12.8 million euros).

SMI launches the new WRAP (then WP) series of wrap-around casepackers. The company’s international expansion starts: the first representative office is opened in Malaysia, and the next year Mexico City’s office is inaugurated as well.

SMIPACK Srl is established as a SMI’s subsidiary company for the manufacture of L-seal hood machines and sealing bar shrinkwrappers.

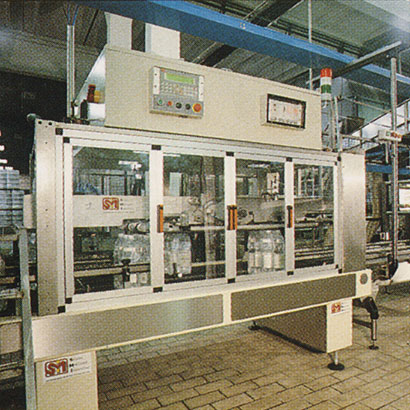

In the same year SMI launches the new models of high speed shrinkwrappers (until 360 packs/minute) of the SK series, which pioneer the machine wiring in fibre optic and a user-friendly operator interface called POSYC.

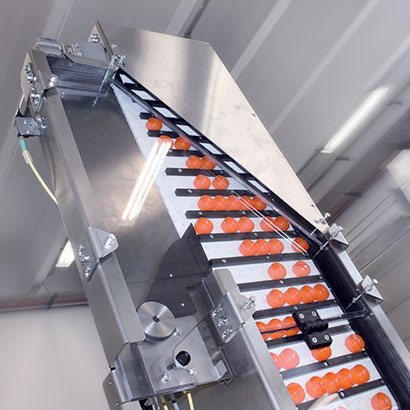

SMI starts Smiline project, a company division created for the production of conveyors and line logistics systems.

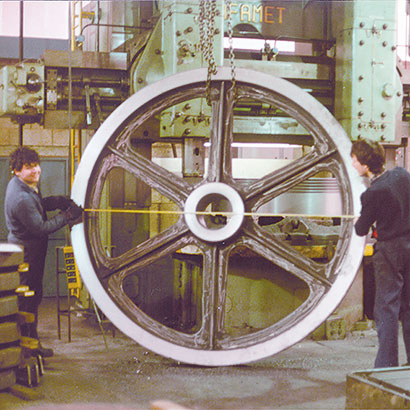

SMI sets up Smiform, a unit specialized in the production of rotary stretch-blow moulders to produce PET containers. In the same year Smimec division comes to light as well for the manufacturing of moulds for stretch-blow moulders, mechanical components and machine frames.

The first 6 and 8 mould models (capable of producing until 12,800 bottles/hour) of the new rotary stretch-blow moulders of SR series are installed.

The establishment of a widespread network of offices abroad (to provide technical and commercial assistance) is the predominant aspect of SMI’s accomplishments in the period between the end of the ‘90s and the early 2000s; in quick sequence SMI USA (United States), SMICentroamericana (Mexico), SMI Do Brasil (Brazil), OOO SMI RUSSIA (Russia), SMI Romania (Romania), SMI POLSKA (Poland), SMI PACIFICA (Australia) branches and China (Nanjing and Guangzhou), France, United Kingdom and Malaysia representative offices are inaugurated.

SMI worldwide success is the result of the accurate study of each single market, of the social-economic aspects of every business area and of the careful analysis of the local clientele’s specific requirements.

SMI produces in a year 319 packaging machines, thus becoming the world’s top manufacturer of this kind of equipment. In addition to that, Smiform division launches larger and more performing stretch-blow moulders and introduces 10, 12 and 14 mould models, capable of producing up to 22,400 bottles/hour.

SMIPACK manufactures over 2,000 L-seal packers and starts to become one of the largest producers of these machines in the world. Always in 2003 SMI, through the new-

established SMIWRAP company, takes over the property and the management of Cartiere Cima papermill, an historical landmark of Bergamo’s entrepreneurship, which has been producing a wide range of food papers for over 100 years.

A year of extreme importance to SMI: the 3,000th shrinkwrapper is delivered and meanwhile the first 20-mould stretch-blow moulders comes into service.

SMI launches SMILAB project, Smigroup’s brand new technological center, whose activities are spread on three laboratories: “Research & Innovation Laboratory”, “Training Laboratory” and “Enterprise Services Laboratory”. All SMILAB activities aim at innovative and sustainable solutions in the industry, energy, social and cultural domains, with high regard for emergent technologies (such as nanotechnologies).

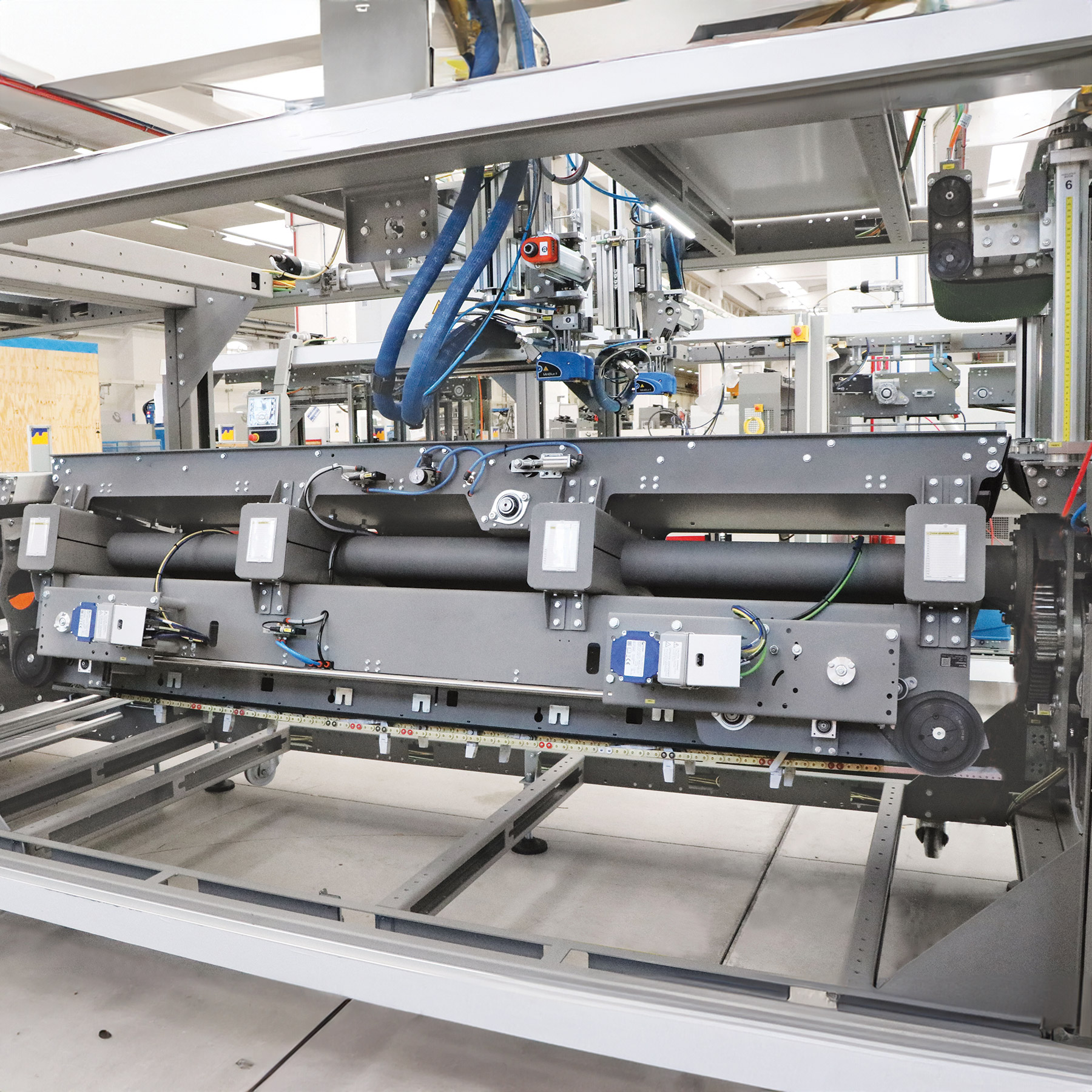

SMI sets up the new Smipal division and at Drinktec 2009 presents the APS 3000, an innovative automatic palletising system for end-of-line operations up to 300 layers per hour.

Smiform division's product range widens to include ECOBLOC® integrated systems, which gather in one single machine the functions of stretch-blow moulding, filling and capping.

SMI installs a complete water bottling line at “Fonte Stella Alpina” production plant called SACS (Stella Alpina Cost Saving), for outputs of 14,400 bottles/hour. It features state-of-the-art technology, compact dimensions, low energy consumption and high operating efficiency.

SMI celebrates its 25th anniversary with the slogan “constantly innovating the packaging industry since 1987”.

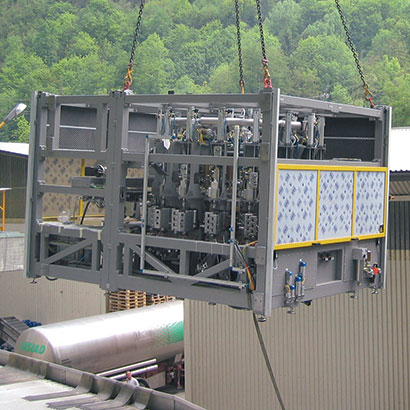

At Drinktec exhibition in Munich, SMI presents a new end-of line compact system called PACKBLOC, which gathers into a single frame the functions of secondary packaging and palletization. The model displayed at the show also includes a SCARA technology articulated arm carrying out the empty pallet handling and interlayer pad inserting operations.

In April SMI's employees move to the new headquarters of the Group, which houses offices and manufacturing facilities on a 65,000 sqm area. The new site, resulting from the renovation of former Cartiera Cima papermill's historical workshops, boasts modern plants generating electrical power from renewable energy sources such as water and sun.

SMI launches the new ERGON series of SK shrinkwrappers, introducing onto the market a newly-conceived range of packers that combines advanced technology and ergonomic design.

At K exhibition in Düsseldorf SMI presents the new EBS ERGON series of fully electronic rotary stretch-blow moulders, equipped with a new energy-saving preform-heating module and with motorized stretching rods.

At Interpack exhibition in Düsseldorf SMI presents the new EBS K ERGON series of ultra-compact, fully electronic rotary stretch-blow moulders, equipped with a new energy-saving preform-heating module integrated with a blowing carousel featuring motorized stretching rods.

SMI launches on the market the new EASY-CAP gravitational cap orientator, that takes caps from a hopper and keeps them in the correct position until they reach the bottling line.

SMI launches on the market the new SFP series of stretch-film packers, which don't need a shrinking tunnel.

SMI rolls out the new ACP ERGON series of pick & place case packers to pack products in RSC cases.

SMI launches on the market the new EBS KL ERGON range of compact rotary stretch-blow moulders, capable of meeting production needs up to 25,000 bottles/hour.

Constant innovation and attention to environmental sustainability led to the development and the launch of the TPP ERGON range, a plastic-free solution for packing cans in multipack through the application of a cardboard pad in the upper part of the pack.

SMI launches on the market the new CM R range of combined packers, equipped with an innovative revolving system for fast and automated format changeover operations.

The study of increasingly compact and versatile solutions leads to the development of new packers with 90 degrees infeed. They include the ASW range of shrink wrappers, the ACW range of wrap-around case packers and the AFCW range of combined packers.

Contact us

- SMI S.p.A.

- Address: Via Carlo Ceresa, 10

24015 San Giovanni Bianco BG

Italy - Phone: +39 0345 40.111

- E-mail: info@smigroup.it

- Monday - Friday: 07:45 - 17:30

Saturday - Sunday: Closed

Privacy statement

DATA PROTECTION AND PRIVACY

The European Regulation 679/2016 (GDPR) on the protection of personal data has been fully applicable since May 25th, 2018. This is an important goal, because it lays down rules relating to the processing of personal data for all Countries within the Union. Every company of the SMI Group planned a series of activities, assets or operational modes to comply with the regulation and put into practice the protection of personal data. Here is a list of actions taken to comply with the European Regulation and our policy on personal data processing.

![]()

Lawfulness of processing

All activities relating to personal data processing shall be lawful (consent, contract obligations, vital interests of the data subject or of third parties, compliance with legal obligations to which the controller is subject, public interest or exercise of official authority, legitimate interest pursued by the controller or by third parties).

![]()

Information document

The information statement has been improved and updated to the new regulations (art. 13 and 14 GDPR).

![]()

Rights of the data subjects (right of access, right to erasure-right to be forgotten, right to restriction of processing, right to object, right to data portability)

Technical and organization measures have been adopted to ensure the data subject's exercise of his rights and to meet the data subject requirements.

![]()

Controllers, processors

Based on the new principle of “accountability”, SMI Group organization was re-defined, in order to proactively ensure integral compliance with the Regulation.

Redefinition of the role of data processors and service suppliers whose activity implies personal data processing.

![]()

Risk of data processing; accountability measures taken by controllers and processors (Impact assessment, record of processing activities, security of processing, data breach)

The “Conformity document”, including records of data processing activity, plans, adopts and demonstrates all technical and organizational measures taken to adequately perform the data processing activities and specifies the necessary procedures to be adopted to notify data breach.

![]()

Transfer of personal data to international organizations

Smi Group adheres to the general principles and guarantees concerning the transfer of personal data to third Countries.

The Controller is:

SMI S.p.A.

Head office: Via Carlo Ceresa, 10 - 24015 San Giovanni Bianco (BG) - ITALIA

P.I.: 04471940165 - C.F.: 03942700166 - R.E.A.: 421708

For further information, write to: privacy@smigroup.net

According to the European Regulation 679/2016, the data subject is entitled to exercise the rights set forth in the Regulation.

The integral version of art. 15; 16; 17; 18; 20; 21; 77 of the European Regulation is attached to this document.

In order to exercise your rights, please send the application form duly filled in to the Controller's address.

Legal notice

SMI S.p.A. con Unico Socio

Società sottoposta a direzione e coordinamento da SMIGROUP S.p.A.

Società appartenente al GRUPPO IVA SMI INDUSTRIES

Sede amministrativa e Unità produttiva:

Via Carlo Ceresa, 10 - 24015 San Giovanni Bianco (BG) - ITALIA

Tel. +39 0345 40.111 - Fax: +39 0345 40.209 - www.smigroup.it

C.F. 03942700166 - P. IVA IT04471940165 - R.E.A. 421708

Iscr.Reg.Imprese 03942700166 - Cap. Soc. € 5.000.000 i.v.

Sede legale: Via Monte Grappa, 7 - 24121 Bergamo (BG) - ITALIA