Newsletter N°6/2009 - Packaging innovation

Packs become "MAXI"

Large supermarket chains' sector is in constant evolution and SMI, one of world's leading manufacturer of packaging machines, meets this sector's latest requirements by proposing high technology equipment and systems, which can effectively satisfy the expectations of each single customer.

In many markets we are currently witnessing an ever-growing demand for bigger and bigger packs, capable of containing a higher number of bottles or cans in order to facilitate storage operations and to speed up the positioning of each single container on the supermarket shelves.

Wrap-around casepacker model WP 600 XL (eXtra Large)

.

The WP 600 XL, a new model of SMI wrap-around casepacker, perfectly expresses the concept of operating flexibility, which is a key feature of SMI end-of-line packaging machines; this newly developed model is capable of producing both "small" fully closed cardboard cases and "big" cardboard trays measuring ¼ and ½ europallet size.

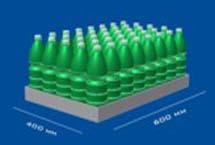

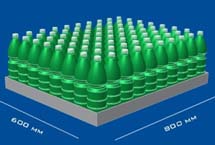

It is a very innovative choice, if we consider that, presently, the production of these two types of packaging solutions requires the use of two different machines: one for the production of cardboard cases in standard formats (2x3, 3x4, 3x5 and 4x6), and another one for the packaging of a huge number of bottles in trays whose size is equal to ¼ or ½ europallet (½ europallet = until 80 bottles). These collations allow to get remarkable savings in terms of production cost for each pack, as well as for storage room and working times.

Latest generation technology, assuring:

.

High operating flexibility > the range of pack formats which can made by the WP 600 XL is remarkably wider and includes both standard size bundles and "maxi" packs of "extra large" dimensions.

Social responsibility > bulky packs are the answer to the growing demand for environment-friendly technological solutions, since the quantity of packaging material employed drastically reduces.

Energy saving > the low consumption of plastic or cardboard packaging material turns into precious energy savings, during the packaging material production, the packaging process and the recycling operations.

Simplified palletisation > palletisation operations speed up and get simpler, as "maxi" size packs require to place a low number of bundles on every layer (just only 2 in the case of ½ pallet format!).

Touble-free storage > if compared to standard sizes, "extra-large" packages allow to remarkably reduce the number of operations to move the products down along the whole distribution chain; moreover, even the "unboxing" of each single bottle and its placement on the shops' and supermarkets' shelves becomes quicker and more efficient, since the operator can save time while emptying out cases and trays.

We invite you to contact our sales department in order to find out the countless benefits of our WP 600 XL, the newer wrap-around casepacker by SMI.

Marketing Department

SMI S.p.A.

E-mail: info@smigroup.it

www.smigroup.it

Contact us

- SMI S.p.A.

- Address: Via Carlo Ceresa, 10

24015 San Giovanni Bianco BG

Italy - Phone: +39 0345 40.111

- E-mail: info@smigroup.it

- Monday - Friday: 07:45 - 17:30

Saturday - Sunday: Closed

Privacy statement

DATA PROTECTION AND PRIVACY

The European Regulation 679/2016 (GDPR) on the protection of personal data has been fully applicable since May 25th, 2018. This is an important goal, because it lays down rules relating to the processing of personal data for all Countries within the Union. Every company of the SMI Group planned a series of activities, assets or operational modes to comply with the regulation and put into practice the protection of personal data. Here is a list of actions taken to comply with the European Regulation and our policy on personal data processing.

![]()

Lawfulness of processing

All activities relating to personal data processing shall be lawful (consent, contract obligations, vital interests of the data subject or of third parties, compliance with legal obligations to which the controller is subject, public interest or exercise of official authority, legitimate interest pursued by the controller or by third parties).

![]()

Information document

The information statement has been improved and updated to the new regulations (art. 13 and 14 GDPR).

![]()

Rights of the data subjects (right of access, right to erasure-right to be forgotten, right to restriction of processing, right to object, right to data portability)

Technical and organization measures have been adopted to ensure the data subject's exercise of his rights and to meet the data subject requirements.

![]()

Controllers, processors

Based on the new principle of “accountability”, SMI Group organization was re-defined, in order to proactively ensure integral compliance with the Regulation.

Redefinition of the role of data processors and service suppliers whose activity implies personal data processing.

![]()

Risk of data processing; accountability measures taken by controllers and processors (Impact assessment, record of processing activities, security of processing, data breach)

The “Conformity document”, including records of data processing activity, plans, adopts and demonstrates all technical and organizational measures taken to adequately perform the data processing activities and specifies the necessary procedures to be adopted to notify data breach.

![]()

Transfer of personal data to international organizations

Smi Group adheres to the general principles and guarantees concerning the transfer of personal data to third Countries.

The Controller is:

SMI S.p.A.

Head office: Via Carlo Ceresa, 10 - 24015 San Giovanni Bianco (BG) - ITALIA

P.I.: 04471940165 - C.F.: 03942700166 - R.E.A.: 421708

For further information, write to: privacy@smigroup.net

According to the European Regulation 679/2016, the data subject is entitled to exercise the rights set forth in the Regulation.

The integral version of art. 15; 16; 17; 18; 20; 21; 77 of the European Regulation is attached to this document.

In order to exercise your rights, please send the application form duly filled in to the Controller's address.

Legal notice

SMI S.p.A. con Unico Socio

Società sottoposta a direzione e coordinamento da SMIGROUP S.p.A.

Società appartenente al GRUPPO IVA SMI INDUSTRIES

Sede amministrativa e Unità produttiva:

Via Carlo Ceresa, 10 - 24015 San Giovanni Bianco (BG) - ITALIA

Tel. +39 0345 40.111 - Fax: +39 0345 40.209 - www.smigroup.it

C.F. 03942700166 - P. IVA IT04471940165 - R.E.A. 421708

Iscr.Reg.Imprese 03942700166 - Cap. Soc. € 5.000.000 i.v.

Sede legale: Via Monte Grappa, 7 - 24121 Bergamo (BG) - ITALIA