Come to K 2019 and discover our eco-friendly solutions

| |||

The role of PET bottles in the circular economy | |||

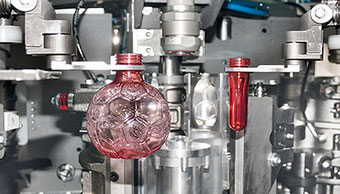

| Packaging sustainability is a key issue, in particular for the beverage industry, in which more and more questions have been raised about the material to be used for packing safely and with limited impact on the environment. At K 2019 trade fair in Düsseldorf, which will be held from October, 16-23, SMI will showcase an EBS 4 K ERGON stretch-blow moulder, a compact, efficient and eco-friendly plant for manufacturing PET and r-PET containers. | ||

| Recent studies have shown the benefits arising from the use of plastic bottles, since this solution is unbreakable, safe, with great barrier properties, lightweight and above all recyclable! In comparison with other packaging materials, such as glass or aluminium, PET has a good environmental profile, mainly thanks to its lightness that translates into less material to produce, less material to dispose of, less energy used to manufacture it and less fuel used for transporting packed products. Thanks to its recyclability and its great weight-capacity ratio, many producers of mineral waters and soft drinks promote and re-evaluate PET and r-PET as convenient and win-win solutions from the environmental sustainability point of view. | |||

| |||

R-PET or lightweight bottles? | |||

Ideal system for producing PET and r-PET bottles | |||

| The use of r-PET (recycled PET) for manufacturing new bottles is the core of the concept of circular economy, that consists of collecting materials after they have been used and processing them, so that they can be reused or recycled. Every time a PET container is recycled, its oil reserve is recovered and reused, eliminating the waste and reducing the packaging environmental impact, provided that efficient systems for managing waste and recycling exist. |  | ||

| Producing even lighter bottles

Another strategy that contributes to the environmental protection is based on the study of even lighter PET containers, that allow to save on plastics and that, indeed, fully comply with the environmental policy of most of the manufacturers of beverages.

| ||

SMI solution for the “green factory”

Available with 2, 3 or 4 cavities, the rotary, compact, efficient and ergonomic stretch-blow moulders from the EBS K ERGON range are perfectly suited to these eco-friendly strategies and to the new manufacturing paradigms of “smart & green factory” | |||

| The EBS K ERGON range is the best solution to produce PET and r-PET containers up to 9,200 bottles/hour.

Thanks to its compact and ergonomic design, it can be installed even on bottling plants with reduced size and it ensures advantages in terms of ease of use and control by the line operator. |  | ||

Meet us at our booth B69 Hall 14 | |||

| If you want to find out further advantages of the EBS ERGON stretch-blow moulders or ECOBLOC® ERGON blowing, filling and capping integrated systems, we will be waiting for you at K exhibition in Düsseldorf, at our booth B69, hall 14, or we invite you to contact our sales department. | |||

Contact us

- SMI S.p.A.

- Address: Via Carlo Ceresa, 10

24015 San Giovanni Bianco BG

Italy - Phone: +39 0345 40.111

- E-mail: info@smigroup.it

- Monday - Friday: 07:45 - 17:30

Saturday - Sunday: Closed

Privacy statement

DATA PROTECTION AND PRIVACY

The European Regulation 679/2016 (GDPR) on the protection of personal data has been fully applicable since May 25th, 2018. This is an important goal, because it lays down rules relating to the processing of personal data for all Countries within the Union. Every company of the SMI Group planned a series of activities, assets or operational modes to comply with the regulation and put into practice the protection of personal data. Here is a list of actions taken to comply with the European Regulation and our policy on personal data processing.

![]()

Lawfulness of processing

All activities relating to personal data processing shall be lawful (consent, contract obligations, vital interests of the data subject or of third parties, compliance with legal obligations to which the controller is subject, public interest or exercise of official authority, legitimate interest pursued by the controller or by third parties).

![]()

Information document

The information statement has been improved and updated to the new regulations (art. 13 and 14 GDPR).

![]()

Rights of the data subjects (right of access, right to erasure-right to be forgotten, right to restriction of processing, right to object, right to data portability)

Technical and organization measures have been adopted to ensure the data subject's exercise of his rights and to meet the data subject requirements.

![]()

Controllers, processors

Based on the new principle of “accountability”, SMI Group organization was re-defined, in order to proactively ensure integral compliance with the Regulation.

Redefinition of the role of data processors and service suppliers whose activity implies personal data processing.

![]()

Risk of data processing; accountability measures taken by controllers and processors (Impact assessment, record of processing activities, security of processing, data breach)

The “Conformity document”, including records of data processing activity, plans, adopts and demonstrates all technical and organizational measures taken to adequately perform the data processing activities and specifies the necessary procedures to be adopted to notify data breach.

![]()

Transfer of personal data to international organizations

Smi Group adheres to the general principles and guarantees concerning the transfer of personal data to third Countries.

The Controller is:

SMI S.p.A.

Head office: Via Carlo Ceresa, 10 - 24015 San Giovanni Bianco (BG) - ITALIA

P.I.: 04471940165 - C.F.: 03942700166 - R.E.A.: 421708

For further information, write to: privacy@smigroup.net

According to the European Regulation 679/2016, the data subject is entitled to exercise the rights set forth in the Regulation.

The integral version of art. 15; 16; 17; 18; 20; 21; 77 of the European Regulation is attached to this document.

In order to exercise your rights, please send the application form duly filled in to the Controller's address.

Legal notice

SMI S.p.A. con Unico Socio

Società sottoposta a direzione e coordinamento da SMIGROUP S.p.A.

Società appartenente al GRUPPO IVA SMI INDUSTRIES

Sede amministrativa e Unità produttiva:

Via Carlo Ceresa, 10 - 24015 San Giovanni Bianco (BG) - ITALIA

Tel. +39 0345 40.111 - Fax: +39 0345 40.209 - www.smigroup.it

C.F. 03942700166 - P. IVA IT04471940165 - R.E.A. 421708

Iscr.Reg.Imprese 03942700166 - Cap. Soc. € 5.000.000 i.v.

Sede legale: Via Monte Grappa, 7 - 24121 Bergamo (BG) - ITALIA